Certified Company

DNV&ABSCertified Company

ISO 9001:2008R&D Production

In China

B 30 7A

B 30 7A material is SAE B 30 (2012) Standard Specification for Copper Alloys in Ingot Form Standard Specification for Copper Alloys in Ingot Form.

Chemical composition of B 30 7A, B 30 7A mechanical properties, B 30 7A datasheet, B 30 7A equivalent grade, Heat treatment and temperature process of B 30 7A.

B 30 7A property sheet

Related Materials

Chemical Composition of B 30 7A

| C: | Max | 0.15 |

| Si: | Max | 1.00 |

| Mn: | 3.75 | 4.75 |

| P: | Max | 0.045 |

| S: | Max | 0.03 |

| Ni: | 9.00 | 10.50 |

| Cr: | 19.00 | 22.00 |

| Al: | Max | Min |

| Cu: | Max | Min |

| Ti: | Max | Min |

| Fe: | Max | Min |

| N: | Max | Min |

| Mo: | Max | Min |

| V: | Max | Min |

Mechanical Properties of B 30 7A

| Rp0.2 (MPa) | 671 (≥) |

| Rm (MPa) | 899 (≥) |

| AKV (J) | 42 |

| A (%) | 32 |

| Z (%) | 14 |

| Hardness | HBW 141 |

B 30 7A shape and dimensions

| B 30 7A Round bar: | 1mm-800mm |

| B 30 7A Square bar: | 10mm * 10mm-600mm *600mm |

| B 30 7A Flat bar: | Thickness:8mm-800mm Width:10mm to 1500mm |

| B 30 7A Sheet or Plate: | Thickness:3mm-80mm Width:1.5mm to 1500mm |

| B 30 7A Strip or Coil: | Thickness:0.1mm-3mm Width:1.5mm-1500mm |

| B 30 7A Forgings: | Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes |

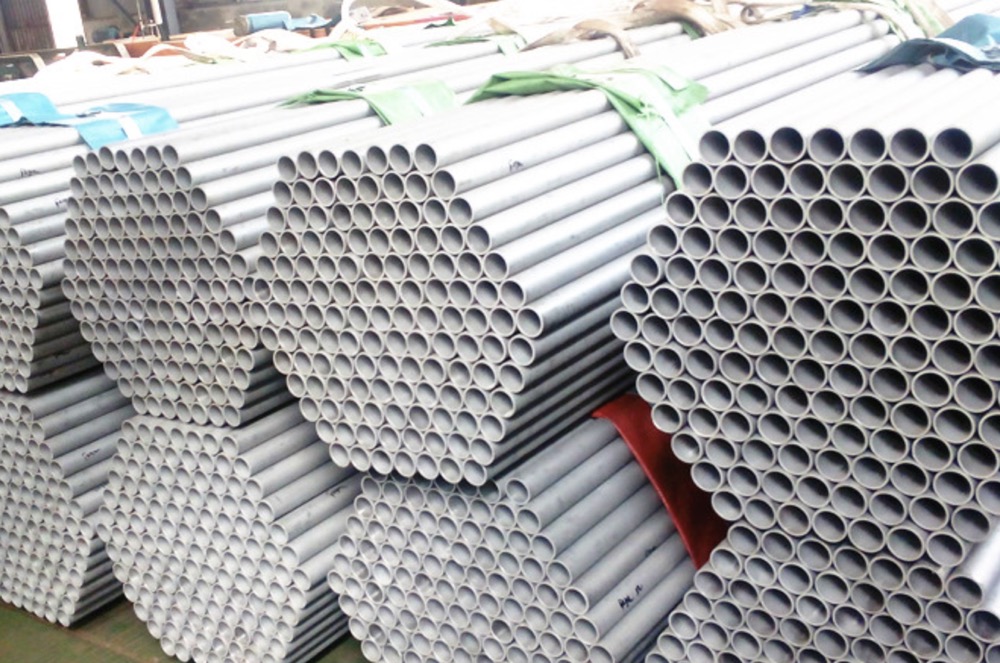

B 30 7A Relevant products

S30403/304L/S30403/1.4307 Tube

S30403 304L S30403 1 4307 Tube

S30453/304LN/1-4311 Tube

S30453 304LN 1-4307

S30403/304L/S30403/1.4307 Tube

S30403 304L S30403 1 4307 Tube

S30453/304LN/1-4311 Tube

S30453 304LN 1-4307

1.4307/S30403/304L Stainless Steel Seamless Tube Pipe

1 4307 S30403 304L Stainless Steel Seamless Tube Pipe