Certified Company

DNV&ABSCertified Company

ISO 9001:2008R&D Production

In China

T11307

T11307 material is High-Speed Tool Steel.

Chemical composition of T11307, T11307 mechanical properties, T11307 datasheet, T11307 equivalent grade, Heat treatment and temperature process of T11307.

T11307 property sheet

Related Materials

Chemical Composition of T11307

| C: | Max | 0.15 |

| Si: | Max | 1.00 |

| Mn: | 3.75 | 4.75 |

| P: | Max | 0.045 |

| S: | Max | 0.03 |

| Ni: | 9.00 | 10.50 |

| Cr: | 19.00 | 22.00 |

| Al: | Max | Min |

| Cu: | Max | Min |

| Ti: | Max | Min |

| Fe: | Max | Min |

| N: | Max | Min |

| Mo: | Max | Min |

| V: | Max | Min |

Mechanical Properties of T11307

| Rp0.2 (MPa) | 648 (≥) |

| Rm (MPa) | 287 (≥) |

| AKV (J) | 22 |

| A (%) | 34 |

| Z (%) | 13 |

| Hardness | HBW 344 |

T11307 shape and dimensions

| T11307 Round bar: | 1mm-800mm |

| T11307 Square bar: | 10mm * 10mm-600mm *600mm |

| T11307 Flat bar: | Thickness:8mm-800mm Width:10mm to 1500mm |

| T11307 Sheet or Plate: | Thickness:3mm-80mm Width:1.5mm to 1500mm |

| T11307 Strip or Coil: | Thickness:0.1mm-3mm Width:1.5mm-1500mm |

| T11307 Forgings: | Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes |

T11307 Relevant products

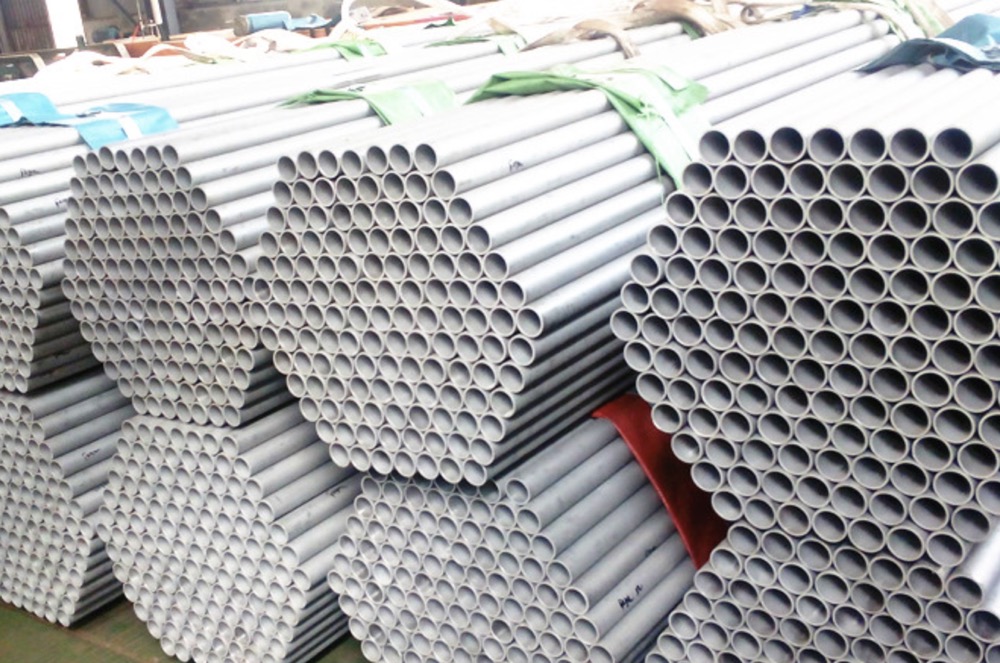

S30403/304L/S30403/1.4307 Tube

S30403 304L S30403 1 4307 Tube

S30453/304LN/1-4311 Tube

S30453 304LN 1-4307

S30403/304L/S30403/1.4307 Tube

S30403 304L S30403 1 4307 Tube

S30453/304LN/1-4311 Tube

S30453 304LN 1-4307

1.4307/S30403/304L Stainless Steel Seamless Tube Pipe

1 4307 S30403 304L Stainless Steel Seamless Tube Pipe