Certified Company

DNV&ABSCertified Company

ISO 9001:2008R&D Production

In China

Nimonic 90

Nimonic 90 material is .

Chemical composition of Nimonic 90, Nimonic 90 mechanical properties, Nimonic 90 datasheet, Nimonic 90 equivalent grade, Heat treatment and temperature process of Nimonic 90.

Nimonic 90 property sheet

Related Materials

Chemical Composition of Nimonic 90

| C | max 0.13 |

| Si | Max 1.0 |

| Mn | Max 1.00 |

| P | Max 0.02 |

| S | max 0.015 |

| Cr | 18.0-21.0 |

| Ni | Balance |

| Cu | max 0.20 |

| Co | 15.0-21.0 |

| B | Max 0.02 |

| Al | 1.0-2.0 |

| Ti | 2.0-3.0 |

| other | Zr max 0.15,Lead max0.0020 |

Mechanical Properties of Nimonic 90

| Rp0.2 (MPa) | 171 (≥) |

| Rm (MPa) | 688 (≥) |

| AKV (J) | 13 |

| A (%) | 34 |

| Z (%) | 22 |

| Hardness | HBW 332 |

Nimonic 90 shape and dimensions

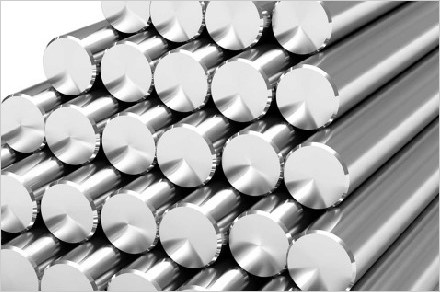

| Nimonic 90 Round bar: | 1mm-800mm |

| Nimonic 90 Square bar: | 10mm * 10mm-600mm *600mm |

| Nimonic 90 Flat bar: | Thickness:8mm-800mm Width:10mm to 1500mm |

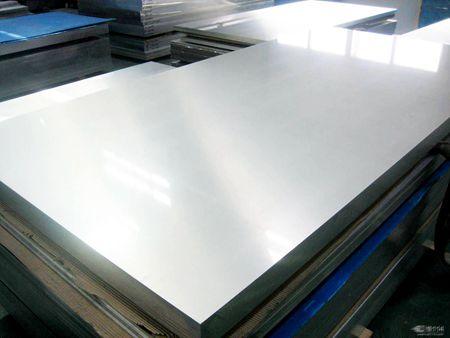

| Nimonic 90 Sheet or Plate: | Thickness:3mm-80mm Width:1.5mm to 1500mm |

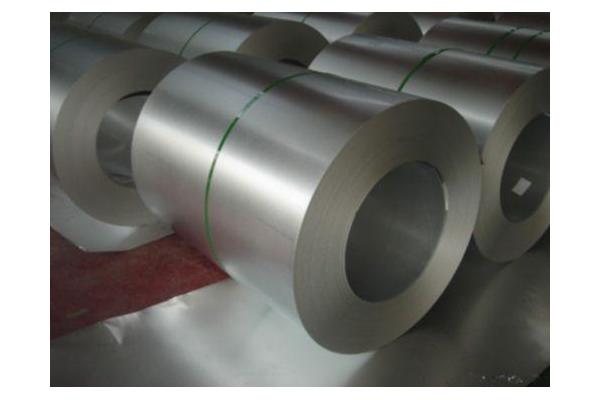

| Nimonic 90 Strip or Coil: | Thickness:0.1mm-3mm Width:1.5mm-1500mm |

| Nimonic 90 Forgings: | Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes |

Nimonic 90 Relevant products

Nimonic 80A / NiCr20TiAl(2.4952) / UNS N07080/ BS 3HR1

GE spec NB 00146, Ideally released to GE spec NB 0014...

SKD-11 Cold working die steel

SKD11 high wear-resisting ductile general cold work die...

X165CrMoV12 Cold working die steel

SKD11 high wear-resisting ductile general cold work die...

17-4ph steel wire

17-4ph steel wire,Hard-Drawn,

A387 F5 / Grade 5 Coil / Sheet

A387 F5 Grade 5 Coil Sheet

D2 Round Bar

D2 Round Bar

P20 tool steel round bar

P20 tool steel round bar

D3 tool steel round bar/plate

D3 tool steel round bar plate

T30402/X155CrVMo121 Die Steel Sheet

Chemical compositionCSiMnCrMoV1 001 000 358 002 000 25Pa...

1.4980 Round Bar

1 4980 Round Bar

DT413 / 4Cr5MoSiV1MOD

High temperature diffusion, superfine crystal(EFS) dispose

1.4980

1 4980 coil,

45Cr14Ni14W2Mo forging

4Cr14Ni14W2Mo steel group is stable, did not occur in ...

D6AC Forging Hollow Bar

The United States began to be developed in the early ...

GH 3536 Sheet

GH 3536 Sheet

UNS NO7718 Coil/Strip/Sheet

UNS NO7718 Coil Strip Sheet

UNS N10276 Coil

UNS N10276 Coil

X65Cr13 profile steel

X65Cr13 profile steel

4145H Hollow Bar

4145H Hollow Bar

95CrV / 9CrV strip steel

95CrV 9CrV strip steel